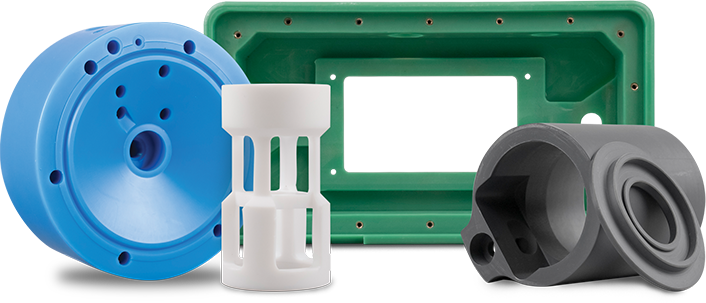

We specialize in the fabrication of small-to-medium sized parts using a wide variety of manufacturing technologies for plastic components. Drawing upon our extensive background of experience, we have the expertise to recommend the best technology for your budget, production volume and timelines.

We proudly represent domestic and global manufacturing sources for custom plastic and rubber fabricated parts. Our supply partners manufacture in a wide selection of thermoplastic and composite materials and technologies including:

|

At HOPEWELL Companies, our objective is to be your single point of contact for make-to-print components using the manufacturing technologies best suited to your design and budget requirements.

While injection molding usually produces the lowest unit cost (at volume), the tooling costs can be jaw-dropping and can often are cost prohibitive. By drawing upon our background of experience, we can often make recommendations for alternative technologies (such as 3D printing or thermoforming) that are better matched to your stage in the product development cycle, your short and long term manufacturing volumes, and of course your budget.

We also have the engineering expertise to be able to make DfM (design for manufacturing) recommendations to help drive out cost while improving overall quality and performance.

We would love to speak with you to better understand your objectives and requirements. Please submit an RFQ, send an email, or call 617 970-5957 for a free consultation to discuss the best manufacturing technology for your next project.

We would love to speak with you to better understand your objectives and requirements. Please submit an RFQ, send an email, or call 617 970-5957 for a free consultation to discuss the best manufacturing technology for your next project.